Test-as-a-Service

Unigen’s test engineering team has over fifteen years of experience in providing testing and validation services, ranging from printed circuit boards to package and die-level processing. We can develop a custom testing plan or standard operating procedure (SOP) based on customer requirements and hardware specifications. This helps determine the appropriate testing equipment and parameters for the testing process. Unigen has dedicated significant R&D resources to developing industrial-grade and robust Reliability Demonstration Test (RDT) programs, supporting customers who need extensive hardware testing to validate component reliability in harsh environments.

Test-as-a-Service Inquiry Form

"*" indicates required fields

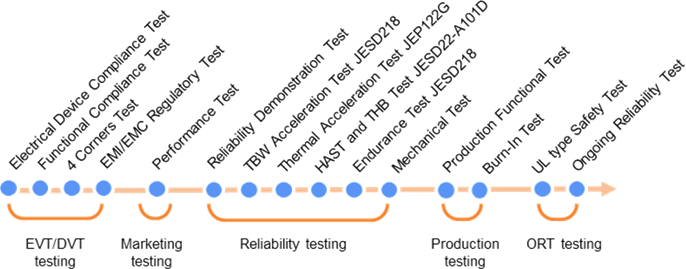

Testing as a Service (TaaS)

Unigen offers a wide range of validation and compliance testing solutions, ensuring that your products meet industry standards for performance, reliability, and safety.

EVT/DVT Testing

- Electrical Device Compliance Test

- Functional Compliance Test

- 4 Corners Test

- EMI/ EMC Regulatory Test

Marketing Testing

- Performance Test

Reliability Testing

- Reliability Demonstration Test

- TBW Acceleration Test JESD218

- Thermal Acceleration Test JEP122G

- HAST and THB Test JESD22-A101D

- Endurance Test JESD218

- Mechanical Test

ORT Testing

- UL Type Safety Test

- Ongoing Reliability Test

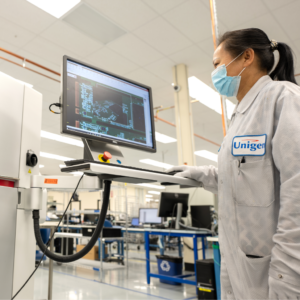

SSD Automation Testing System

Unigen’s SSD Automation Testing System offers high-efficiency SSD testing, ensuring precise control and seamless integration with traceability systems.

- Auto handing (load/unload) of the “U.2 PCIe SSD” by 6-axis-robots for testing.

- Maximum 80 testers with 1,600 products per test cycle.

- Auto control test temperature (same as burn-in chamber)

- Two drawer panels for up to 240 DUTs loading

- Auto link the test result/logs to traceability system

Test Capability

- Static temperature burn-in chamber

- Flying probe

- In-circuit Testing (ICT)

- Hi-pot testing

- Automated Optical Inspection (AOI)

- Automated X-Ray Inspection (AXI)

- 3DX

- 5DX

Validation Coverage

Prototype

- Mechanical Design

- Schematic Design

- Prelim-BOM

- PCB Layout

- Final Gerber & BOM

- Material Purchases

- NPI Build

EVT

- Board Bring Up

- Power Character

- SI, P/I Measure

- Electrical Functional Tests

- Performance Tests

DVT

- Compatibility Tests

- 4-Corner Test

- S/I Margin Test

- Regulatory Test

- RDT

PVT

- QS Samples Qual

- Traceability Reports