Virtual Factory Tour

If you don’t have the opportunity to visit Unigen’s facilities to see how our (or your) products are made, we welcome you to explore them through our Virtual Tours of our Newark, California, and Hanoi, Vietnam factories. Now, you can easily access our interactive facility maps from anywhere, at any time.

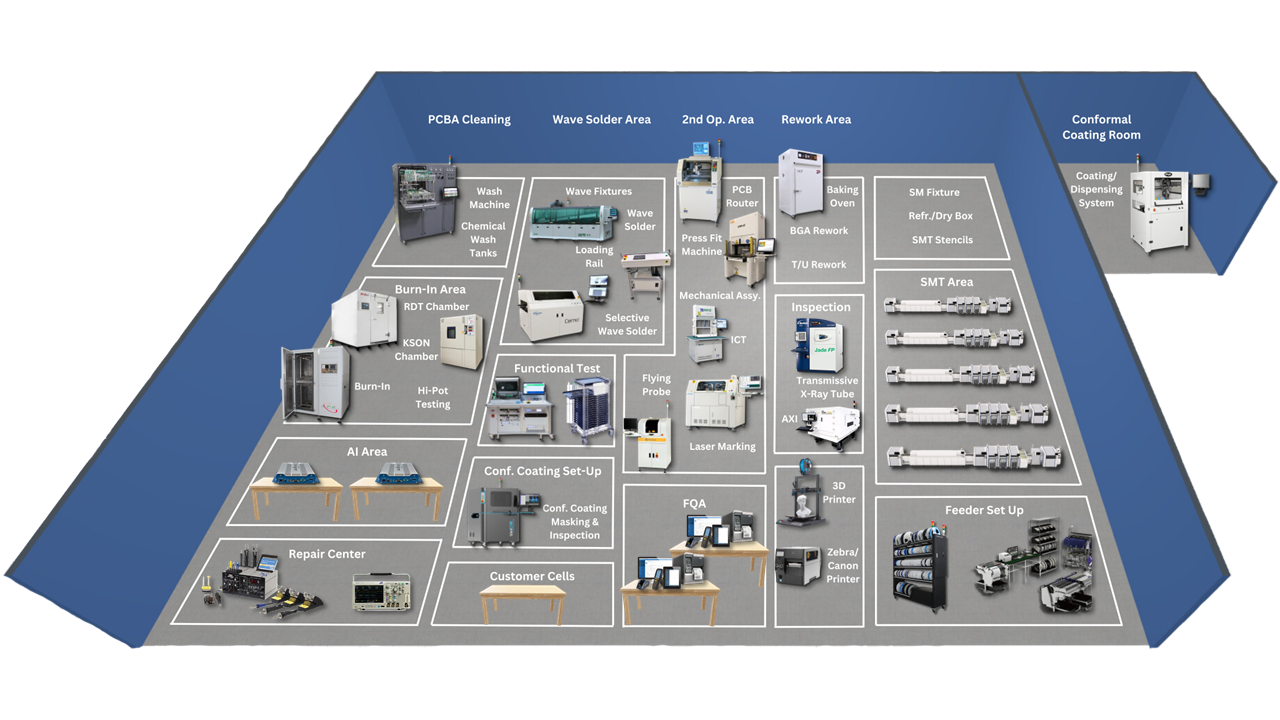

US HEADQUARTERS

Newark, CA

Surface Mount Technology (SMT)

- Purpose: Places surface-mount devices onto a printed circuit board (PCB)

- Key Features: Production floor equipped with 5 SMT Lines, large panel production, low impact placement, dual lane placement, 3D coplanarity check that removes faulty parts

3D Solder Paste Inspection (SPI)

- Purpose: Inspects solder paste deposit quality on PCBs. Detects both catastrophic failures and quality failures in the solder paste deposits.

- Key Features:

- 6,400 mm2/sec inspection speed at 18μm resolution

- Operator can remove a defective PCB from within the machine

- High-precision 0201 pad inspection

Reflow Oven

- Purpose: Melts the solder paste on the PCB to create solder joints.

- Key Features:

- 6 upper and 6 bottom forced hot air convection zones allow high quality lead-free soldering with uniform heating and exceptional process stability

- Temp. accuracy ±1°C and a high-speed CE certificated blower for maximum convection

Automated Optical Inspection (AOI)

- Purpose: Checks for defects in printed circuit board assemblies (PCBAs).

- Key Features:

- Rigid gantry structure and exclusive dual-motor drive system

- High resolution linear scale provides high accuracy positioning

- CoaXPress camera delivers faster inspection and measurement processes

Automated X-Ray Inspection (AXI)

- Purpose: Checks for defects in PCBAs

Key Features:- Fully automatic inspection of hidden solder joints with X-Ray images

- Solder joints inspection in several layers

Transmissive X-Ray Inspection

- Purpose: Displays a real time image of the solder joints that one cannot see by visual inspection

- Key Features:

- 1.33 Mpixel @ 10fps Long

- Lifetime CMOS flat panel detector with real-time image enhancements

- Geometric Magnification 1400X, System 4200X

Flying Probe

- Purpose: Measures each component of a PCB in turn to check that it is in-place and of the correct value

- Key Features:

- Breakthrough 4-heads & 6-flying probes system

- Safe and highly accurate measurement system

- Strong and rigid XY stage

- Key Features:

Baking Oven

- Purpose: Removes moisture from components that are moisture sensitive

Key Features: Can heat items from ambient (room temperature) +25°F to 450°F

Pressfit Machine

- Purpose: Inserts compliant pin connectors into PCBs

Key Features:- Semi-automatic pressing of compliant pins

- Ability to control & monitor force, distance, and speed

RDT Chamber

- Purpose: Tests the effects of specified environmental conditions on electronic devices and components.

- Key Features:

- Temperature range of -80°C to +100°C

- Excellent temperature uniformity

- Multiple cooling circuits and techniques

- Redundant / mission critical design criteria

PCB Router

- Purpose: De-panels PCBs through a router bit that minimizes stress on the components

- Key Features:

- Max cutting speed is 50mm/ sec

- Traveling speed 8000 mm/ sec

- Built-in fixture-based dust vacuum system

- Machine can shift up to 5 depths

Wave Solder

- Purpose: Wets the exposed metallic areas of the board (not protected with solder mask) creating a reliable mechanical and electrical connection.

- Key Features:

- Manual conveyor angle adjustment between 5 to 7 degrees

- Rotary chip wave & lambda

- Temperatures up to 215ºC

- Recipe control single-nozzle spray fluxer

- High-velocity convection topside preheaters

Wash Machine

- Purpose: Washes the PCBAs with DI water (in-line washer) or Chemicals (batch washer)

- Key Features: Built-in process monitoring

3D Printer

- Purpose: Prints 3D models from a CAD file designed by engineering with materials such as ABS, PLA, etc.

- Key Features:

- Allows for a flexible design and rapid prototyping

- Produces strong, light-weight parts while minimizing waste

Conformal Coating

- Purpose: Protects the entire assembled parts or area from moisture, dust, and other harsh conditions

- Key Features:

- Secondary moisture cure mechanism for curing in the non-UV exposed shadowed area

- Fluoresces under UV light to allow for coating inspection

Laser Marking

- Purpose: Marks products that need an identification mark for tracking or recognition.

- Key Features:

- Marks non-metallic surfaces including ceramics, glass, and plastics

- Mark is permanent and consumable costs are low

- Produces a laser cell with a small footprint

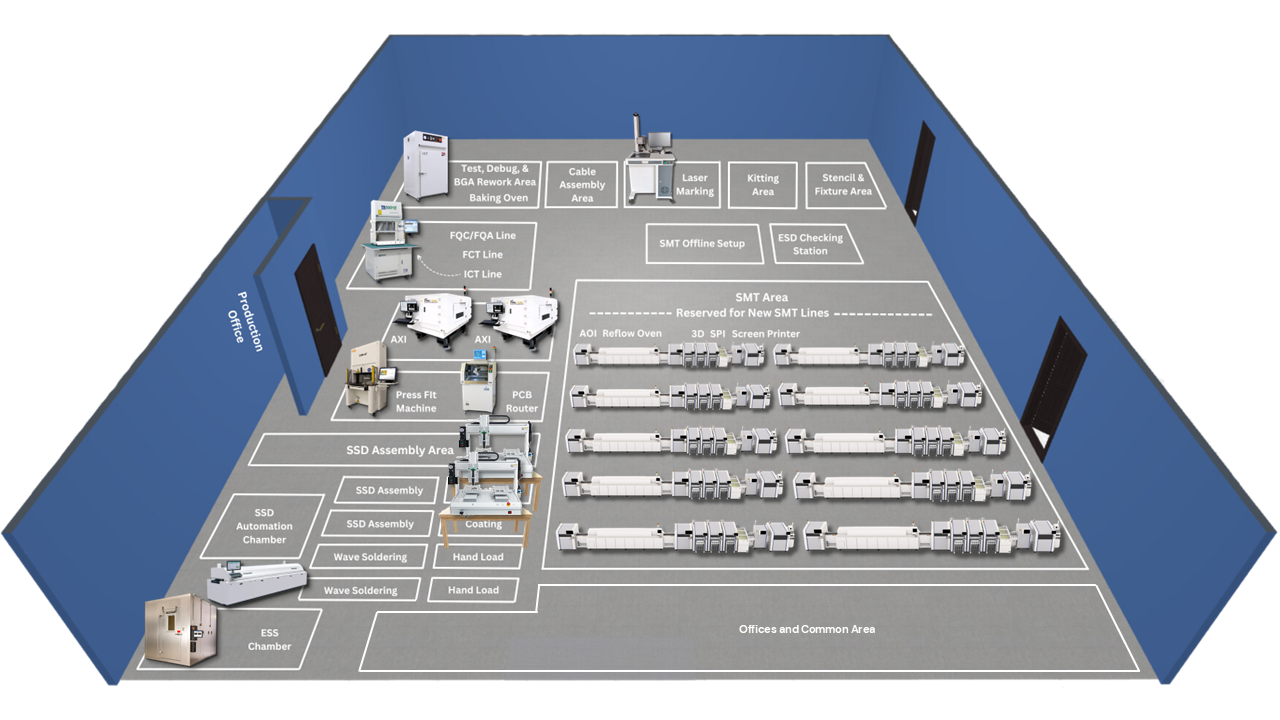

Hanoi, Vietnam

Surface Mount Technology (SMT)

- Purpose: Places surface-mount devices onto a printed circuit board (PCB)

- Key Features:

- Production floor equipped with 12 SMT lines

- Large panel production

- Low impact placement and dual lane placement

- 3D coplanarity check that removes faulty parts, panel warpage check, quick-change feeder carts and nozzle banks

- Lightweight 16-nozzle head with increased placement accuracy

Automated Optical Inspection (AOI)

- Purpose: Test for defects in printed circuit board assemblies (PCBAs)

- Key Features:

- High-speed color multi-angle inspection of up to 01005 components

- High-defect coverage using hybrid 2d+3d inspection technology

- True 3D profile measurement using dual laser units

- Rapid programming interface with auto library and offline editing

Reflow Oven

- Purpose: Used to melt the solder paste on the PCB to create solder joints

- Key Features:

- 8 heating and 2 cooling zones

- Maximum setpoint temperature of 350°C

- Active forced convection top and bottom cooling cells

- Closed-loop convection control

3D Solder Paste Inspection (SPI)

- Purpose: Inspects solder paste deposit quality on PCBs. Detects both catastrophic failures and quality failures in the solder paste deposits.

- Key Features:

- Multi-angle 3D side view

- 5 camera inspection

- Metrology-grade measurements

- SmartWarp compensation eliminates local PCB deformation

- AI-powered algorithms with smart programming

- Industry 4.0 ready platform

Screen Printer

- Purpose: Prints solder paste onto a surface mount assembly forming the PCB with the use of a metal mesh or stencils.

- Key Features:

- 510 x 510mm (optional 650mm long board kit) and auto pin setup for high mix environments

- Print capability to process microchip, to bumping, to pin-in-paste applications

Automated X-Ray Inspection

- Purpose: Test for defects in printed circuit board assemblies (PCBAs)

- Key Features:

- Three-dimensional analysis of solder joints

- Accurate and repeatable measurements with high call accuracy

- Pin-through-pin (PTH) wetting coverage & head-in-pillow (HIP) inspection capability

In-Circuit Test

- Purpose: Measures each component of a PCB in turn to check that it is in-place and of the correct value.

- Key Features:

- Modular upgrade options from Manufacturing Defect Analyzer (MDA) to ICT and functional test

- High fault coverage test solution

- Limited access solution and functional test expansion using PCI Extensions for Instrumentation (PXI) modules

Laser Marking

- Purpose: Marks products that need an identification mark for tracking or recognition.

- Key Features:

- Marks non-metallic surfaces including ceramics, glass, and plastics

- Mark is permanent and consumable costs are low

- Produces a laser cell with a small footprint

Baking Oven

- Purpose: Removes moisture from components that are moisture sensitive

- Key Features:

- Bi-metal thermostat

- Temperature accuracy of ±3°C

- Temperature is controlled by PID digital microprocessor, gravity convection (GCE), or Air Forced (AFE)

Press Fit Machine

- Purpose: Inserts compliant pin connectors into PCBs

- Key Features:

- Semi-automatic pressing of compliant pins

- Ability to control & monitor force, distance, and speed

PCB Router

- Purpose: De-panels PCBs through a router bit that minimizes stress on the components

- Key Features:

- Max cutting speed is 50mm/ sec

- Traveling speed 8000 mm/ sec

- Built-in fixture-based dust vacuum system

- Machine can shift up to 5 depths

Environmental Stress Screening (ESS) Room

- Purpose: Tests the effects of specified environmental conditions on electronic devices and components.

- Key Features:

- Excellent temperature uniformity

- Multiple cooling circuits and techniques

- Redundant / mission critical design criteria

- All major subsystems procured from world class manufacturers